News

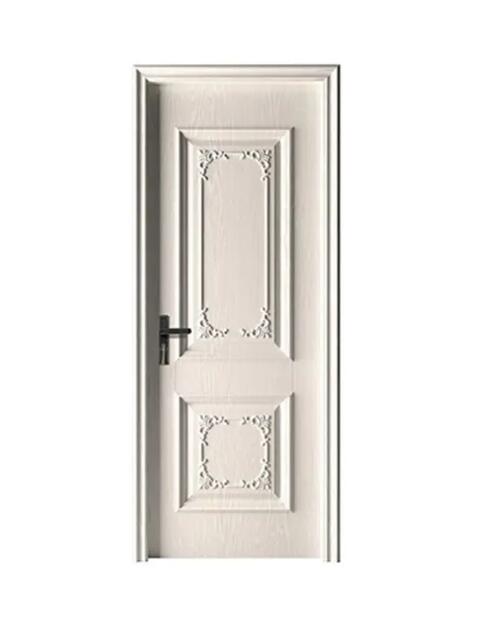

Waterproof WPC Door Factory Introduces The Features Of Wpc Doors

Waterproof WPC Door Factory introduces the features of WPC doors:

1. Green and environmentally friendly, the raw materials used in the wood-plastic set door are one-time molding under high temperature, high pressure, and vacuum conditions, the material does not contain formaldehyde, and the secondary processing adopts thermal transfer technology, free of paint, and there is no toxic during production and use. Harmful gases and odors are released, and it is a human-friendly product that meets the environmental protection standards of modern interior decoration.

2. Waterproof, moisture-proof, anti-corrosion, mildew-proof, moth-proof, and non-deformation. WPC products have the dual characteristics of wood and plastic. Therefore, in addition to indoor doors, WPC doors are especially suitable for places with large temperature differences, humidity, and poor ventilation, such as wet bathrooms, which need anti-corrosion, mildew-proof and moth-proof. storage room etc.

3. Reasonable structure, high strength, special row cavity structure design, to ensure the ideal internal structure of the wood-plastic foam material, coupled with excellent formula design and reasonable production process, to ensure the strength of the product.

4. The installation structure saves time and effort in installation. The wood-plastic door adopts the quick-install structure imported from Germany, and the door cover is very convenient to install. The door cover wire and the door cover are connected by bayonet, without gun nails or glue fixing.

5. The products are serialized, with many designs and colors, and strong matching. According to different market demands, Benben has designed two forms of the integral door and welded door. Integral doors are available in dozens of surface designs, and welded doors can provide profiles for door and window assembly plants. Wood-plastic material has the processing performance of solid wood, which can be planed, sawed, drilled, milled, and glued, and is also suitable for traditional woodworking processing technology.

The size of the door cover is equipped with 8-10 specifications for selection according to different wall widths. The colors of the set doors are available in black walnut, teak, American cherry, white oak, and mahogany.

6. Good thermal insulation and sound insulation performance. The material used in the wood-plastic set door has a uniform and fine cells and its specially designed row cavity structure, which ensures that its thermal conductivity is lower than that of ordinary plastic materials and its noise reduction performance is better. After testing, the heat transfer coefficient of this product is 1W/m2.k, and the thermal insulation performance reaches the first level of GB/T16729-1997; the sound insulation performance level is 6, which has good thermal insulation and sound insulation performance.

7. Good flame retardant performance, the wood-plastic suit door will not support combustion in case of an open fire, and it will automatically extinguish after being left alive.

8. Significant cost-effective advantages, industrialized manufacturing, stable quality, economical cost, and product prices are often competitive.

English

English عربى

عربى 中文简体

中文简体